Richard Craddock was born into a cycling family, so it was inevitable that he would throw his leg over a bike and start racing. Less inevitable perhaps was his involvement in the industry, but that wasn’t what inspired him to start building his own carbon frames. It was frustration instead, at not being able to find a mass-produced frameset that fitted him perfectly.

His first prototype generated enough interest for Richard to consider building a business around his new bike. The idea dove-tailed nicely with a growing interest in bike-fitting, plus there was the allure of putting his name to his own product. After so many years of working for, and representing, other brands and manufacturers, the time was right for him to establish Craddock Cycles.

Craddock is an exacting individual and approaches framebuilding as a scientist. In the first instance, he spent a lengthy period developing the main tubes of the frame in conjunction with a specialist manufacturer of carbon tubing. Once built, he rode the bike hard for 12 months and conducted his own lab tests to validate his work. The final design easily satisfied EN14781, the rigorous European safety standard for road bikes.

Where so many brands look to the East for manufacturing and supply, Craddock is intent on keeping as much of his business in the UK as possible. The main tubes are made in the UK, and in time, so will be the forks and stays, but for now they come courtesy of Dedaccai. Craddock himself handles every step of production (except painting) with a modest schedule yielding around 25 framesets/year.

Craddock Cycles recently appointed Goldstein Cycles as its Australian agent, and with that came the opportunity to ride the first Craddock to land here.

Before the Ride

A bespoke frameset normally starts life with a conversation between the customer and the framebuilder, and is crucial for Richard Craddock. “Each rider has their own unique history, experience, flexibility, injuries and future plans,” he says. “Two riders of the same stature may need very different frames. Therefore I don’t use prescriptive fitting formulae, but instead talk through as much of the rider’s cycling history as possible.”

The goal of this conversation is to accurately position the customer’s contact points—the saddle, pedals and handlebars—to achieve a comfortable and effective position on the bike. “If they’ve been riding in a bad position,” says Richard, “I need to know what led to that set up, how long have they been riding like that, and how willing and able they are to make changes for a better position.”

As the local agent for Craddock, Mark Hoyer of Goldstein Cycles makes sure that Richard gets all of the information he needs to start designing the new bike. He takes measurements from the customer’s body and bike and highly recommends a professional fit.

“My time with Legend, and now Craddock, has taught me that the key contact points are a good starting point if you have been fitted before. From here you can get the frame to fit you with the type of riding you like. This is super important. I want the customer to be comfortable and confident on their bike.”

Once the contact points have been established, Craddock can start work on the bike’s geometry as well as fine-tuning the main tube construction to suit the rider’s weight and performance needs. “I design the frame’s geometry to best support the rider in their position,” explains Richard. “I aim for a neutral, balanced feel to the bike.”

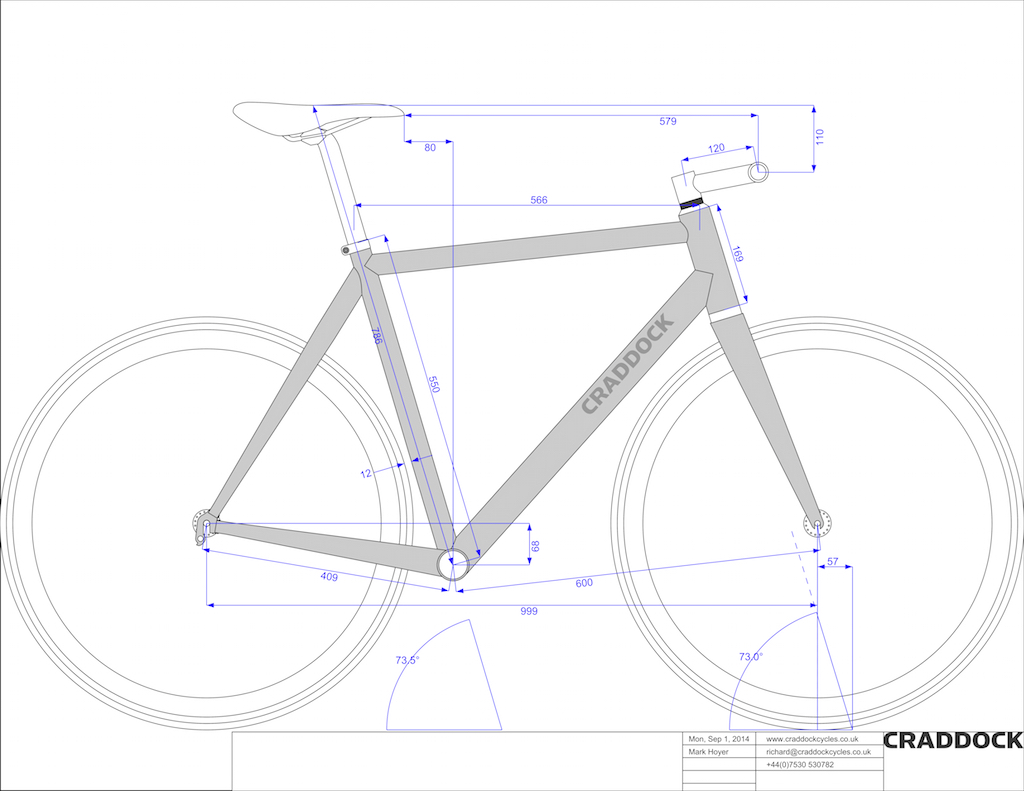

In this instance, the brief for Richard was, “a bike that wasn’t twitchy, something that is comfy yet responsive to sudden accelerations with a short wheelbase to suit crits.” The latter was easily defined since the customer’s current ride had a wheelbase over 100cm, so the goal was to accommodate the contact points within a wheelbase less than 100cm. The final design of the frameset is shown below:

At present, Craddock offers one frameset design that features a 1.5 inch headest and a Pressfit 30 bottom bracket. Internal routing is provided for electronic transmissions, while external cable stops are moulded into the frame for mechanical groupsets. Frame weights (excluding forks) are around 1,000g for small sizes and up to 1,200g for large sizes.

Craddock uses tube-to-tube construction for his frames. While he doesn’t share the details on his construction process, it is clear from his published photos that preparation is key. One of his main priorities is to conserve the integrity of the carbon, hence the cable stops and bottle cage bolts are moulded into the frame to avoid drilling any holes.

Australian buyers can expect to pay $5,900 for a custom Craddock carbon frameset, with a disk brake option that adds $660. The frameset is supplied with a Hope integrated headset and seat clamp. Craddock bonds the headset into the frame rather than relying on an interference press fit. He also installs the Pressfit bottom bracket bearings before the frame leaves the workshop.

Also included in the standard price is an unlimited choice of main paint and logo colours with a matte or gloss finish. In addition, Craddock is happy to work with any customer that has additional artwork requirements.

The frameset reviewed here was assembled with a SRAM Red22 groupset; Zipp’s 404 Firecrest clinchers, carbon seatpost, alloy bars and stem; and Arundel carbon bottle cages for a final weight (sans pedals) of 7.12kg.

In building the bike, I was impressed with the preparation of the frame. The inside of the seat tube, for example, was as smooth and well finished as the outside. There is plenty of appeal in the simple, clean lines of the frameset, and despite all of the oversized tubing, there is a great sense of balanced proportions.

The thick, lustrous orange finish and masked logos were beautifully rendered however there were a couple of small areas (in between the wishbone of the seatstays and behind the headtube) where the paint was thinner upon close inspection. It’s one of the few steps in the production process that is beyond Richard’s direct control (painting is outsourced) but it’s something that he is currently refining. “I strive for perfection and will do all I can to make good bikes for clients. Falling short hurts.”

At present, time to delivery is roughly 14 weeks. For more information see Craddock Cycles and Goldstein Cycles.

After the Ride

From the outset, it’s important to note that the frameset reviewed here was not built to suit my fit. It was a little longer and taller than my ideal, so I needed a shorter stem (100mm instead of 120mm). It was a small compromise but I kept thinking about it while I was riding this bike.

So how good was the Craddock? The handling, the responsiveness, the quality of the ride, they were all pitch-perfect in a way that I’ve only experienced on a few occasions. So I had to ponder, how much better could it have been if it had been built to suit me?

The handling enabled the bike to corner very easily and sharply without ever being demanding. I’m certain this bike will serve its owner well for the criterium season.

Carbon has proven to be the ideal material for constructing an efficient frame that can offer immense responsiveness without undue discomfort. And when carbon is done well, when the blend is perfectly tuned, then it makes for a bike, like the Craddock, that is both exciting and enjoyable to ride. Every kick spurred this bike on but there was no downside to all that efficiency, not even on harsh chipseal roads.

Which brings me to the quality of the ride. Riding the Craddock was a stirring experience: it has a liveliness, an energy, that resonated deeply. I started riding extra miles just to enjoy the sensation.

Perhaps the Craddock would not have been such a good match for me if I’d been much taller or shorter, lighter or heavier than it’s owner. Or maybe there is a measure of wiggle-room in any good bike design, and some variations in stem length and saddle positioning can be tolerated. Ultimately, the suitability of any frameset rests with how readily and accurately the rider can assume his or her ideal riding position, and in this instance, it was a very simple matter.

The Zipp 404s proved to be a great match for the Craddock. They encouraged the efficiency of the bike without undermining its handling. Indeed, a little something was lost when I switched to low profile alloy rims. Perhaps it was the difference in weight or the density of the rims, because it dulled the quality of the ride, just a little, but it was enough to notice.

Final Thoughts and Summary

Any rider considering a bespoke frameset can look forward to collaborating with the framebuilder to create a bike that will serve all of their needs. As such, bespoke bikes are best suited to experienced riders that have a clear idea of their needs, or for those riders that have a fit that can’t be met by mass-produced brands. Such a personalised service justifies at least some of the asking price for a Craddock.

When put up against similarly priced framesets on offer from much bigger brands, Craddock’s carbon frameset compares well: first, there is the efficiency of a well-tuned race frame; second, impeccable handling that inspires confidence; and third, a blend of comfort that defies the bike’s responsiveness. However, there is more on offer – custom geometry, refinement of the design to suit weight and performance needs, and unlimited paint options, plus an exceptional ride quality – more than enough to justify the rest of the asking price.

Image gallery

WRAP-UP

- High quality constrcution

- Custom geometry

- Impeccable handling

- Sublime ride quality

- Unlimited colour choices

- High end pricing

- Minor imperfections in paint finish