In this week’s Bikes of the Bunch we feature a little known German bike brand called VANDEYK.

The particular bike belongs to Dylan VanWeelden who works with American-based component maker, Chris King. As Dylan explains, the bike’s birth was because of the death of another.

“Out of the blue you get run over by a truck, break more bones than you can imagine and live through it to see another day. Two years later you manage to hobble around and struggle with constant pains but on the bright side of life you land a bike like this. To some it looks like another yuppie rig riding down to the coffee shop. But to me it’s what happens when you get an insurance bike.

“I was looking for a custom carbon fiber bike to replace my destroyed carbon race bike from my accident. I already have a steel Cielo Sportif which gives me everything I need for the comfort of a plush steel bike and allows me to hit all of the #gravelvision I need. My quiver needed a high performance race bike.

“Working for Chris King I see and meet nearly all of the boutique bike builders around the world. This makes choosing your next bike a daunting task. At Eurobike I ran into the crew from Vandeyk and had an affinity towards the attention to detail and the beauty in their bikes. Knowing I could never afford one I just drooled from afar. When my insurance company was fixing to replace my crashed whip I had endless options. Coming from the custom bike building side of things I really wanted a bike made specifically for me.

“There are not many companies doing full custom carbon manufacturing. Racing bikes I’ve been through my fair share of carbon bikes. I’ve broken more than I can count, fixed them and broke them again. Vandeyk worked with me to create a bike with all of the ride characteristics that I desired. I wanted a bike that was durable and sturdy since I weigh 200 pounds but still be as vertically supple as possible to comfort all my injuries. In the end I couldn’t be happier with landing this Vandeyk Machine for Riding.”

Build Details:

- VANDEYK Machine for Riding frame

- Shimano Dura Ace Di2 grouppo

- ENVE Smart 3.4 hoops with Chris King Sour Apple R45 ceramic hubs

- ENVE bar, post and painted to match stem and fork

- Chris King Headset

- Fizik Saddle

- Chris King Press Fit 24 Bottom Bracket

For those of you unfamiliar with the VANDEYK brand, it were founded in 2011 by owner Arendt van Deyk who worked in the creative area of Mercedes-Benz Global for 15 years.

Arendt told us: “There is an open approach to collaboration, which means for each collection and concept, we are constantly integrating interesting collaborators and bright minds from both Design / Creative as well as Craftmanship / Technology. So to say a multidisciplinary collaboration of experts from their fields.”

On the technical side of things, Arendt explains how the frames are built:

“The ‘Machine for Riding’ was our first Carbon / Composite collection. For the construction we worked with Ralf Brand, a Formular 1 proven engineer to develop the frame construction, and for the frame production we have partnered up with ax-lighntess in Germany, where all frames are fully handcrafted in Germany.”

VANDYKE’s “Machine for Riding” collection introduces a machine ‘code’ system to which all key design elements are translated - going as far as the downtube logo.

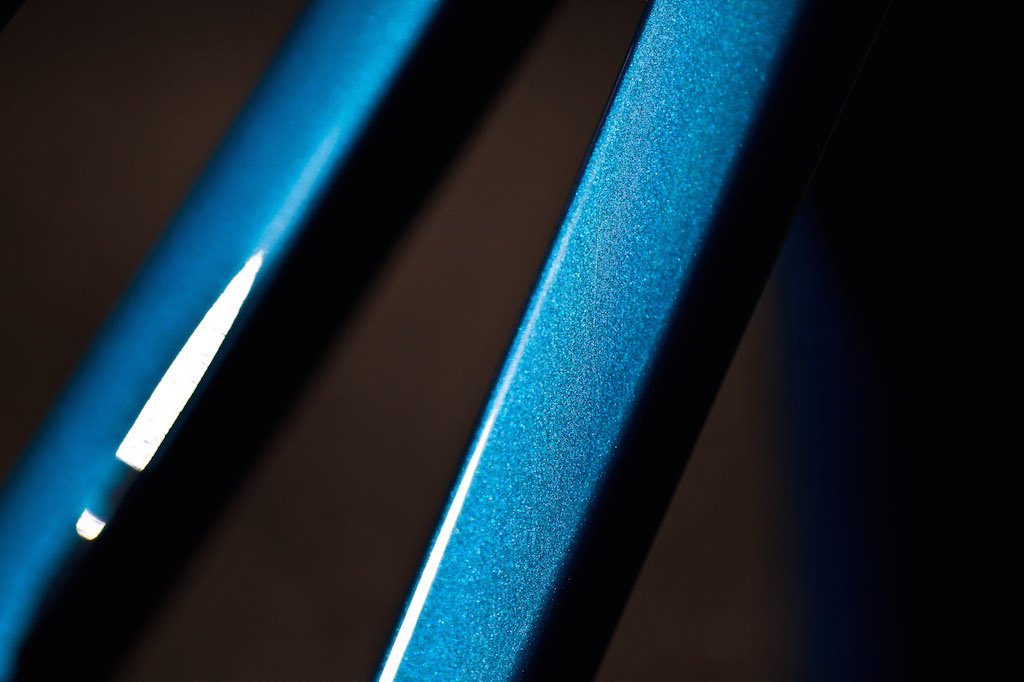

Arendt van Dyke says, “A very high effort is also made in the paint job, where we paint the frames (liquid paint) in collaboration with a partner usually painting super sports cars, in a pretty meticulous process.”

Arendt van Deyk says, “Engineering and material selection is focused on an excellent stiffness to weight ratio, including a bold bottom bracket area (BB86 standard) as well as a tapered 1,5″ fork.”