Australia’s first and only WorldTour cycling team has 28 riders, 3 concurrent race programs, a dozen Subaru team cars, two vans, three trucks, two buses and more than 30 staff, including mechanics, warehouse managers, soigneurs, finance officers, logistics officers, directors, and so on. This requires a lot of equipment, office facilities, and a warehouse to keep it all running smoothly.

The logistics of coordinating everyone on the team (which includes the non-riders too) is extremely challenging. Riders come and go from different places around the world, equipment needs to be maintained, schedules need to be kept.

The manager of the service course, Jacopo Scampin, told us that Varese isn’t the nicest place in Italy (but we thought it was pretty beautiful), but from a logisitcs point of view it works very well with the Milan Airport (Malpensa) being only 20 mintues away and the Swiss and French borders being close by.

There’s nothing flashy about any service course I’ve ever been to and GreenEDGE’s is no exception. It’s a nondescript warehouse with parking for a fleet of vehicles, stores of food and drink, administration offices, kitchen and laundry facilities, a mechanics area, and a huge storage area full of bikes, wheels and components.

It was both a good time and a bad time for us to be visiting the service course and showing it to you. There is very little racing on at the moment and everything is gathered here getting prepared for the Tour de France. Vehicles are getting serviced, new bikes are being built (sorry, we can’t show them to you yet), new kit is arriving, gear is getting sorted out. We’re told that it’s a disaster area compared to normal, but it didn’t seem terribly messy to us. Have a look at the photos we took as we toured the facility.

- The outside of the service course is nothing but a nondescript two-level warehouse. On the bottom level GreenEDGE keeps all their equipment, and the upper level is where the U23 and women’s squads keep all their equipment.

- GreenEDGE has two buses. The riders refer to one as the “good bus” and the other one is apparently not as desirable. The first bus is new (as of last year) and the second bus came from Rabobank.

- Inside the “good bus”. The only difference between a “team bus” and a regular bus is that a team bus isn’t open to the public. It’s simply a bus with a coffee machine, a fridge, a couple showers at the back, and a lounge/changing area.

- The driver’s seat

- The mechanics’ trucks house every imaginable spare part for the bikes including dozens of cassettes, stems, saddles, seatposts, etc.

- The truck is nearly empty at the moment.

- Spare helmets, race radios, TT helmets, and a good stock of regular food that goes on tour with the buses.

- One of the most fascinating things to me while touring the service course was the logistics spreadsheets hanging on the walls. It shows how much planning and preparation goes on behind the scenes to run a WorldTour team. The top left spreadsheet shows the team’s vehicle race schedule, service schedule, specifications, etc. The top right photo shows a pile of Tour de France equipment that grew to a mountain throughout the day. The bottom spreadsheet shows the riders’ race schedule throughout the season.

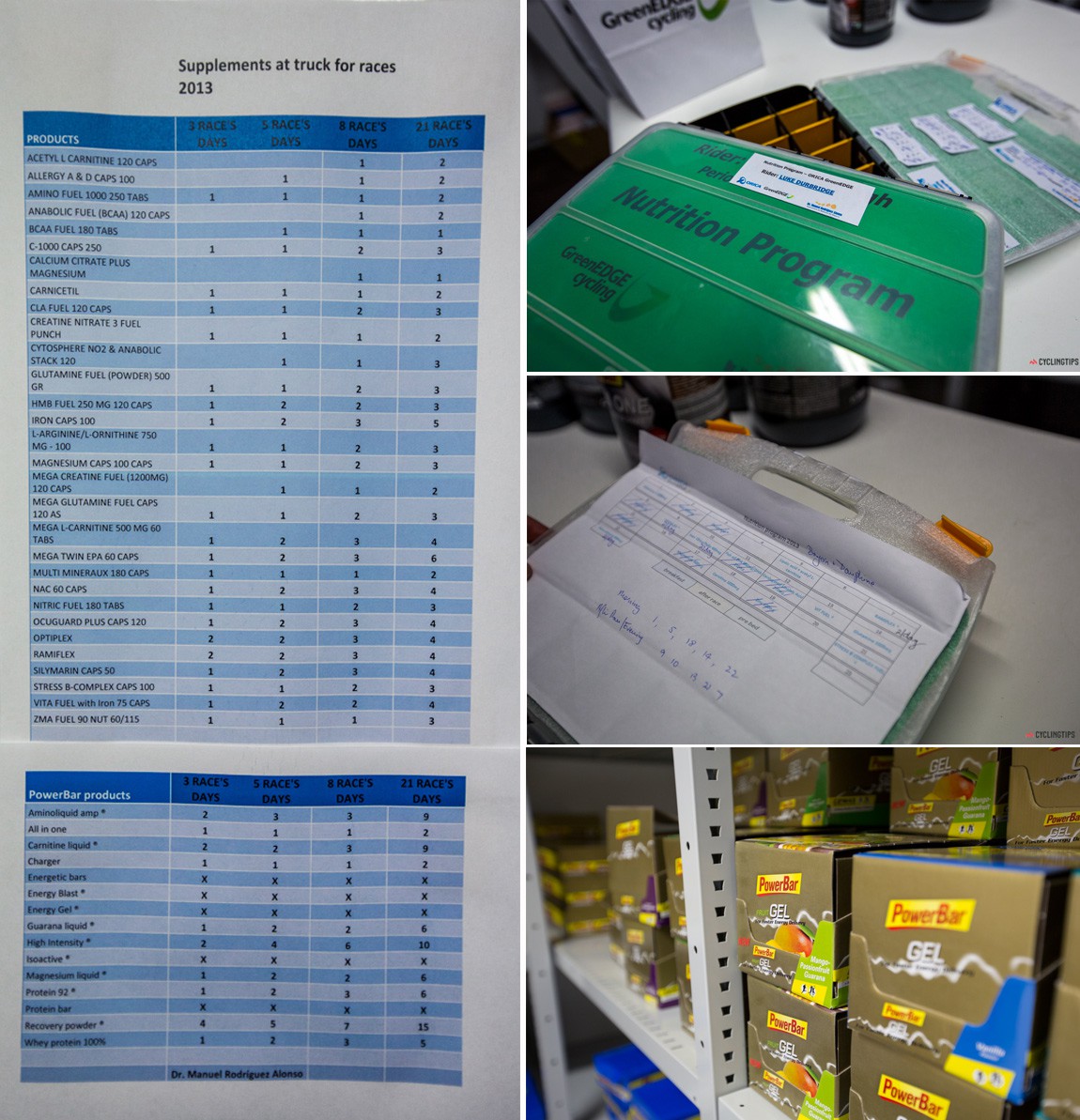

- Even the nutritional programs are mapped out for every rider and every race. Each rider has a case of supplements which are divvied out per day according to the riders’ needs.

- Four separate work benches with tools in the mechanic’s area.

- We can’t show you the new Scott Addicts, but they’ll be released next week at the Tour de France. These are the new TT bikes being built up for the Tour.

- We’re not exactly sure which rider used this bike at the Olympics, but it’s a beauty.

- A view of the equipment room from the entrance

- An opposite view of the equipment room (facing back towards the mechanic’s room and vehicle parking)

- Dozens of wheels with glue drying for new singles.

- The old singles.

- Durbridge’s old TT bike. All the new ones are getting built up before the TdF.

- The bikes and wheels that were used in the Classics.

- A view from the small kitchen to the three offices that keep GreenEDGE ticking along.

- This is the master spreadsheet which sits outside of the admin offices. It shows the schedule of every event, every staff member, every team vehicle. Susan Stewart (David McKenzie’s wife) is the Logistics Manager and obviously very handy with Excel.

- Boxes of swag coming in for all the riders (new jeans, shirts, kit, sunglasses, etc)

- Not only does the service course house all the equipment and vehicles, it also stores all the trophies that didn’t get taken home by the riders. This can sometimes be a problem for the riders when the trophies are massive and are difficult to take on a plane.